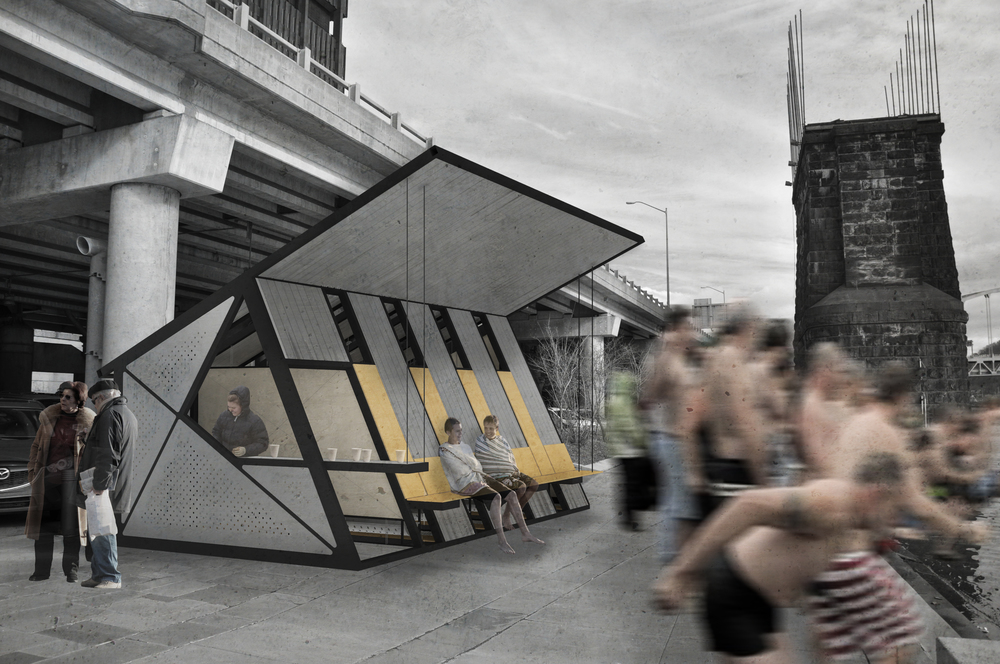

The Hot Seat Changing Booth

January 2015 | Third-Year Studio II, Spring 2015 Semester

1st Place Prize, EPIC Metals Competition

In collaboration with Bobby Esposito

The Hot Seat is conceived of as a quickly mountable and demountable changing hut for the Pittsburgh Polar Bear Club, which each New Year’s Day holds a polar dive into the freezing Monongahela River.

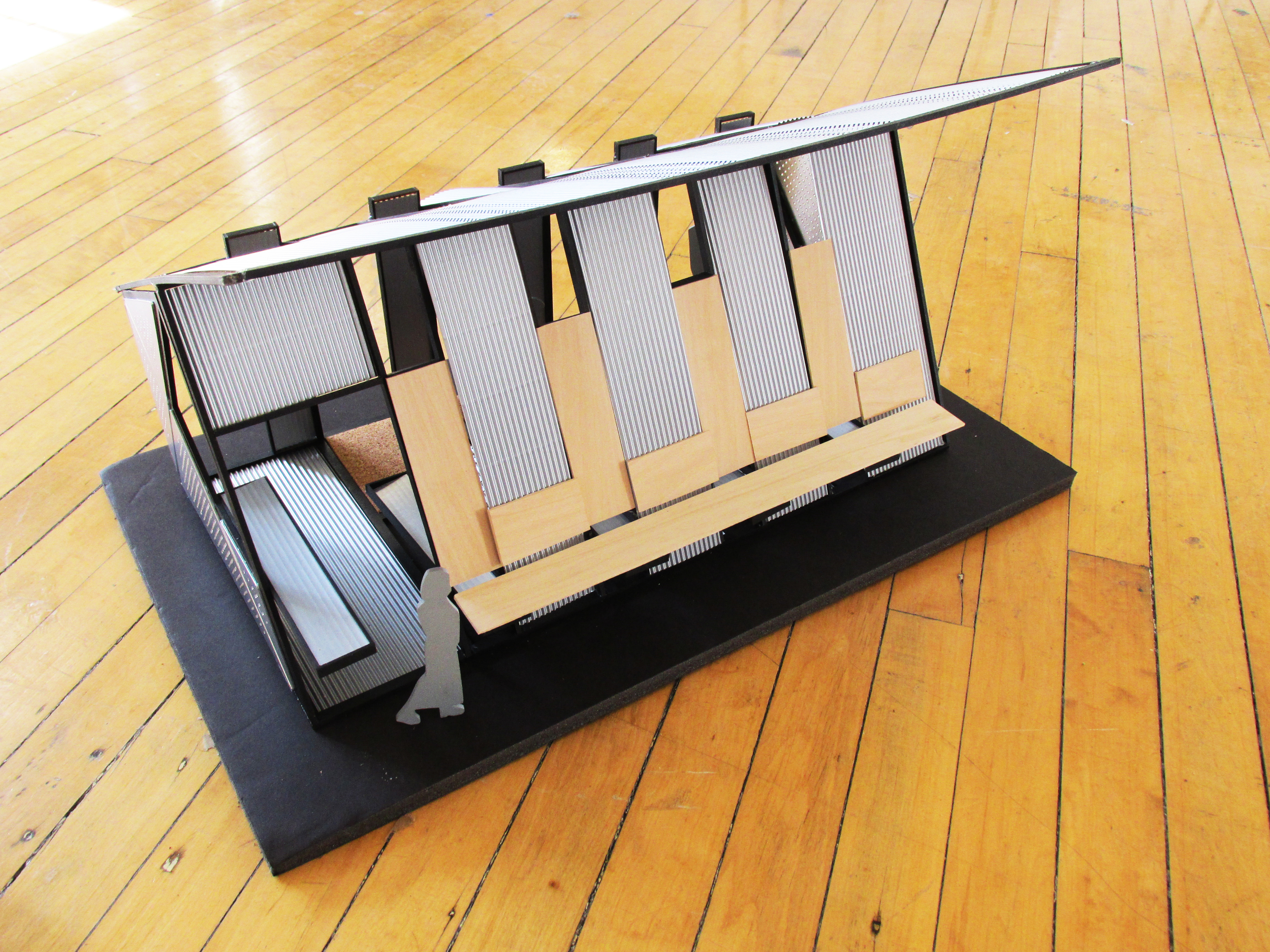

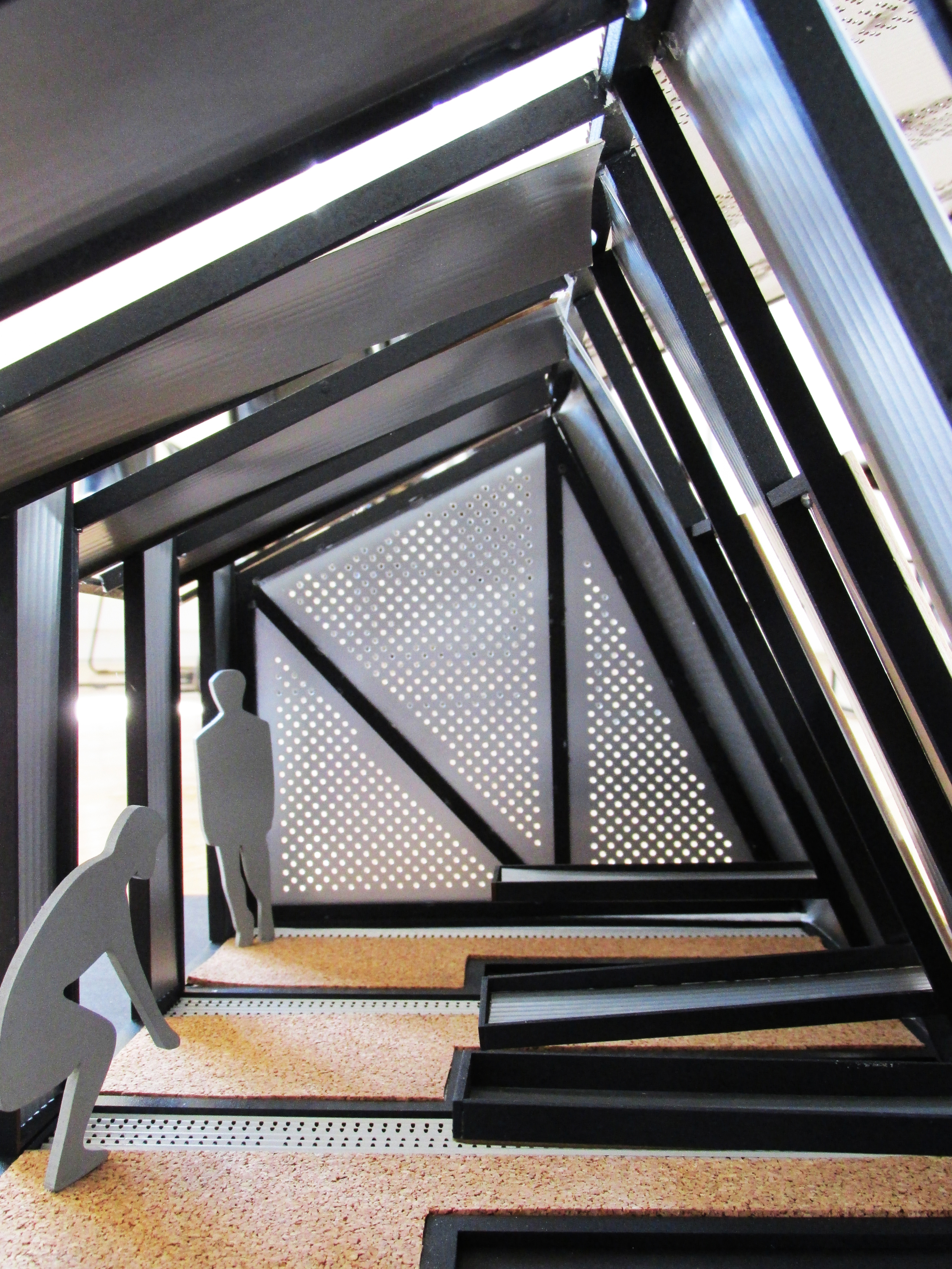

Given a week to figure out the intriguing problem of building a warm enough changing hut out of a material like metal decking that could also be built and unbuilt in one day, Bob and I decided to use the decking in unconventional ways. We framed the decking with lightweight steel members. These frames flat-pack when not in use, but have self-locking hinged portions that swing out to create walls, roofs, and floors, as may be seen in the Construction Sequence drawings. Essentially, the framed panels are self-scaffolding, easing the burden of construction.

Curved, perforated sunshade decking became coal heaters for the changing room benches: hence the name “The Hot Seat.” We also laid the changing booth floors with cork and included a hot-drink bar in the hut, a benefit to spectators and participants alike in the detestable January weather. Exterior plywood benches provide seating for spectators or recovering divers.

The intended spirit of The Hot Seat is best explained by our project narrative, which bears repeating: “The dive into the frigid waters of the Monongahela can be described as quick and exhilarating. ‘The Hot Seat’ strives to be just that. The design marries the precise, thin, and reflective nature of the metal decking with the stark, raw quality of steel members to create a structure that celebrates the vibrancy of metal. The interior changing rooms contrast the cold exterior with the warmth of cork-lined floors, canvas partitions, and seats heated by coals. The entire structure is designed for extremely fast assembly and disassembly, using self-locking hinge joints. Within the structure you can experience a blend of elements that is not only useful but comfortable as well.”

Bobby and I received the 10th Annual Epic Metals Competition first-place prize for our work on this project.